Recent Projects

Engineering Solutions Tailored to Your Project’s Needs—Maximizing Value, Minimizing Risk.

Each Unique Project is Evaluated to Determine the Right Amount of Engineering to Maximize Value for Our Clients

At CUE EPCM, we recognize that every project in the upstream and midstream sectors is unique. To maximize value, we evaluate each project's complexity, scope, risks, budget, and timeline. This enables us to tailor the engineering approach and deliverables, ensuring the right level of rigor without over-designing or underestimating. By aligning our solutions with your project’s specific needs, we provide cost-effective, efficient designs that mitigate risks, streamline execution, and optimize long-term performance.

- All

- Compressor Station

- Emissions / Environmental

- Enhanced Oil Recovery

- Modular / Standardization

- Oil Battery

- Operating Issue

- Optimization

- Pipelines

Operational Issues: Uncontrolled Venting/Flaring, Multiple VRU’s Seized, EPA Shutdown Threats

$32M oil facility near the NM border was losing 800 BBL/day, flaring black smoke, and facing shutdown threats from regulators and the midstream. Oxygen infiltration and seized VRUs added to the crisis. We were brought in to help stabilize and solve it.

Read More Full-Scope Engineering & IFC Delivery in 60 Days

Supported a $10MM UL development with 4 wellpads, gas lift/oil pipelines, and major CTB upgrades. Issued IFC drawings in 60 days, coordinating with drilling, completions, and reservoir teams. Delivered full ME, EE, process, drafting, and project management scope.

Read More 14 MMSCFD Gas Lift Compression

14 MMSCFD Gas Lift Compression at recently upgraded CTB. We installed a compressor station with 3 Cat 3516’s, 4″/6″ gas lift pipelines, and scrubbers, supporting 14 wells. No shutdown needed, H2S management with Triazene, and provisions for future expansion. Total AFE: $3MM.

Read More EPCM Delivery of Full-Scale $4MM Facility Expansion in Eagle Ford Play

Brownfield CTB expansion to support 8 new off-lease wells with modular design, dual-phase separation, gas compression, and vapor recovery. Provided full EPCM services to support clients’ scalable development in the Eagle Ford and Austin Chalk plays.

Read More Optimizing Emissions Control and Safety for Sustainable Operations

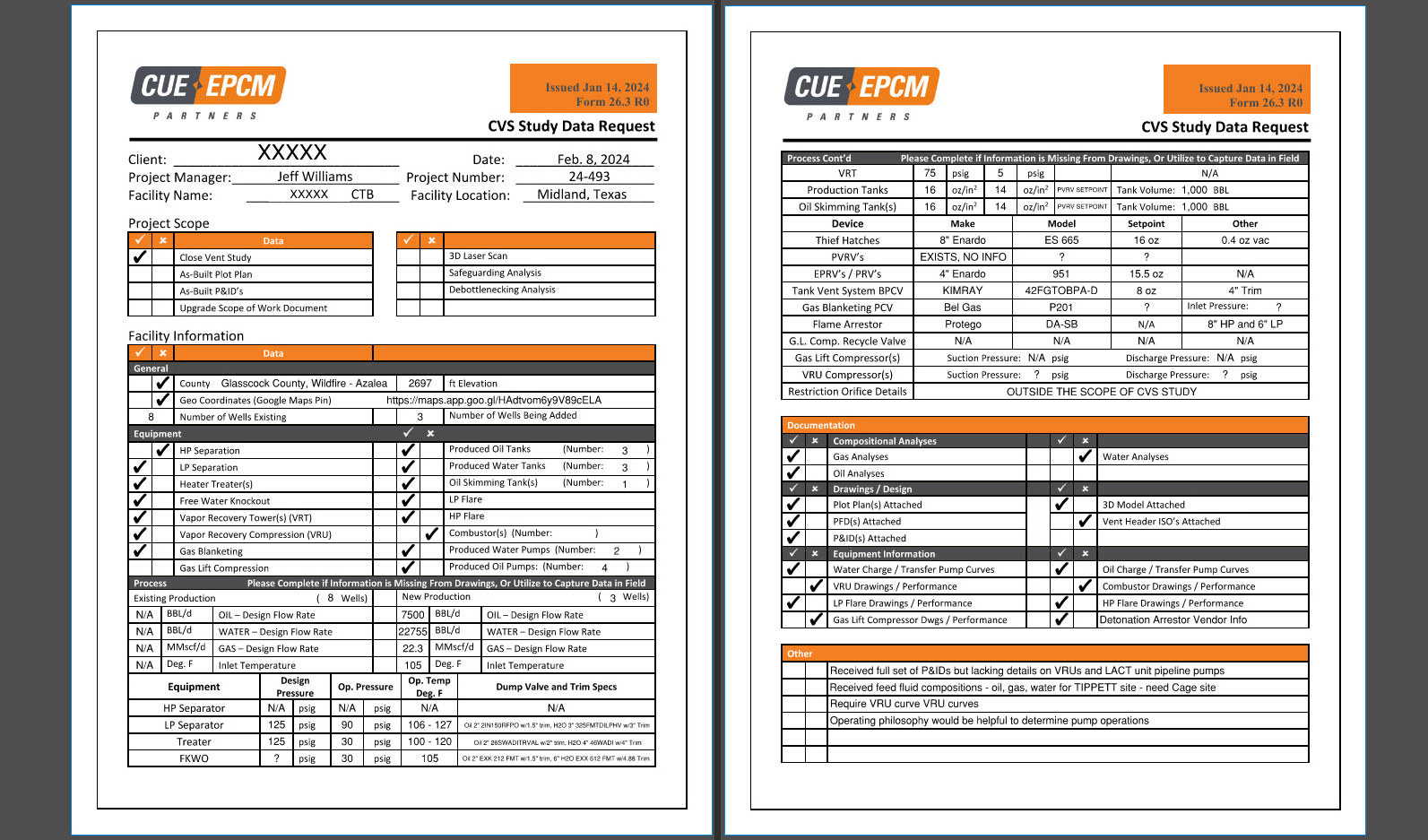

We completed CVS & Safeguarding Studies for a 7,500 BBL/d battery in the South Midland Basin, recommending venting upgrades, added monitoring, and VRU improvements. Proud of our process—ask us for examples and let us help meet your environmental goals!

Read More From Expansion to Optimization: Full-Cycle Support in the Delaware Basin

Brought deep familiarity to a major Delaware oil battery where we previously participated in a large expansion. Recently optimized vapor recovery, cutting costs with a phased VRU replacement plan and tailored deliverables—maximizing long-term value and efficiency.

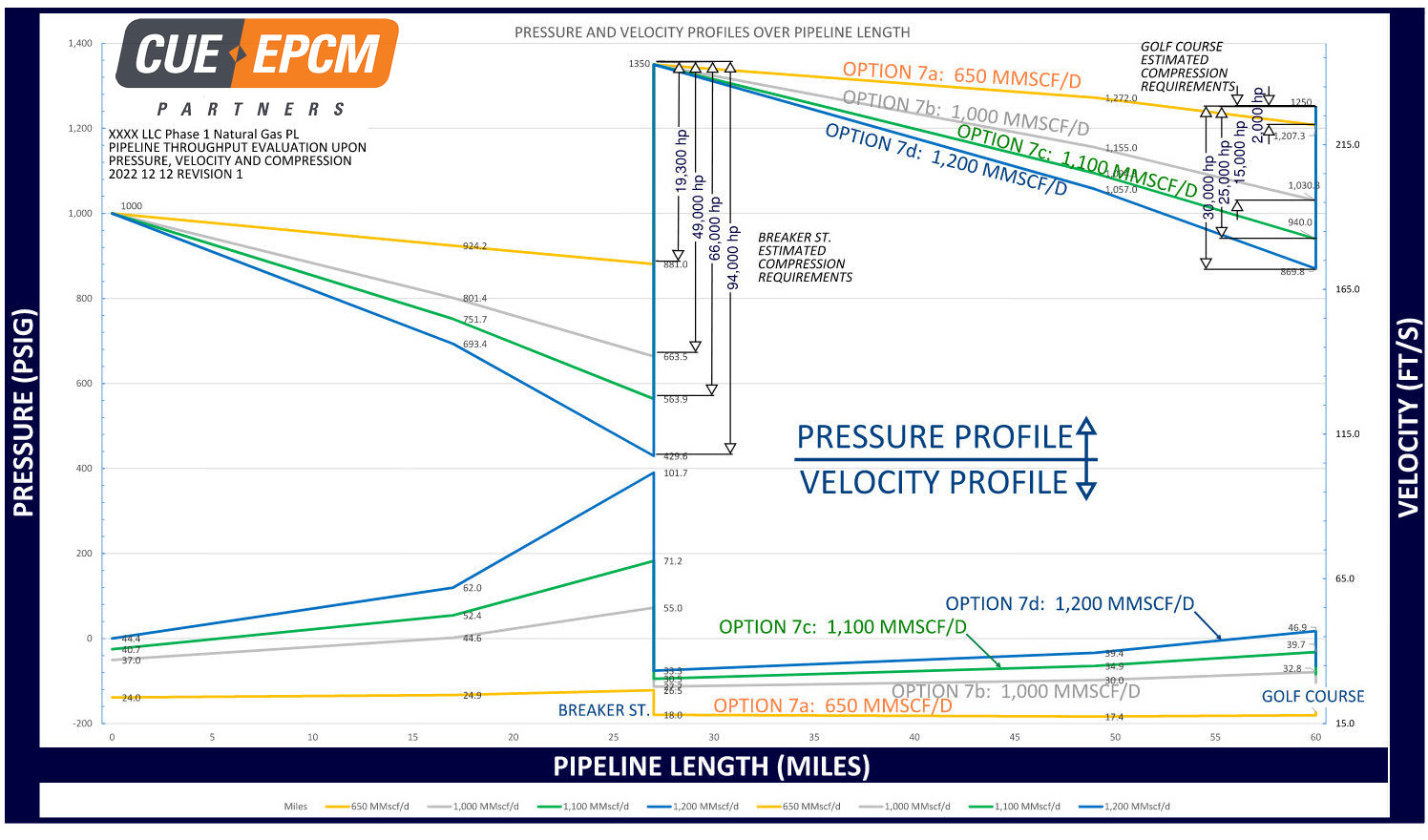

Read More Maximizing ROI on a 60-Mile Gas Pipeline Through Smart Design

CUE supported the design of a 60-mile, 1.2 BCF/d gas pipeline with 124,000 HP compression through a mid-sized city. Using Pipeflo simulation, we optimized pipeline specs and compression to align budget, routing, and ROI in a highly iterative design process.

Read More Pressure Reduction & VRU Optimization at Delaware CTB

CUE uncovered major pressure constraints while optimizing VRUs at a 14-well CTB, enabling up to 50 psig reduction, improved vapor recovery, and increased production. Our tailored solution cut flaring, boosted efficiency, and included a complete bid-ready package.

Read More Maximizing Throughput: Delaware CTB Capacity & Upgrade Study

CUE assessed a Delaware Basin CTB for tie-in feasibility, analyzing capacity, identifying key upgrades, and sizing pipelines. We delivered a full AFE-ready package with cost estimates and scope to support confident decision-making for new developments.

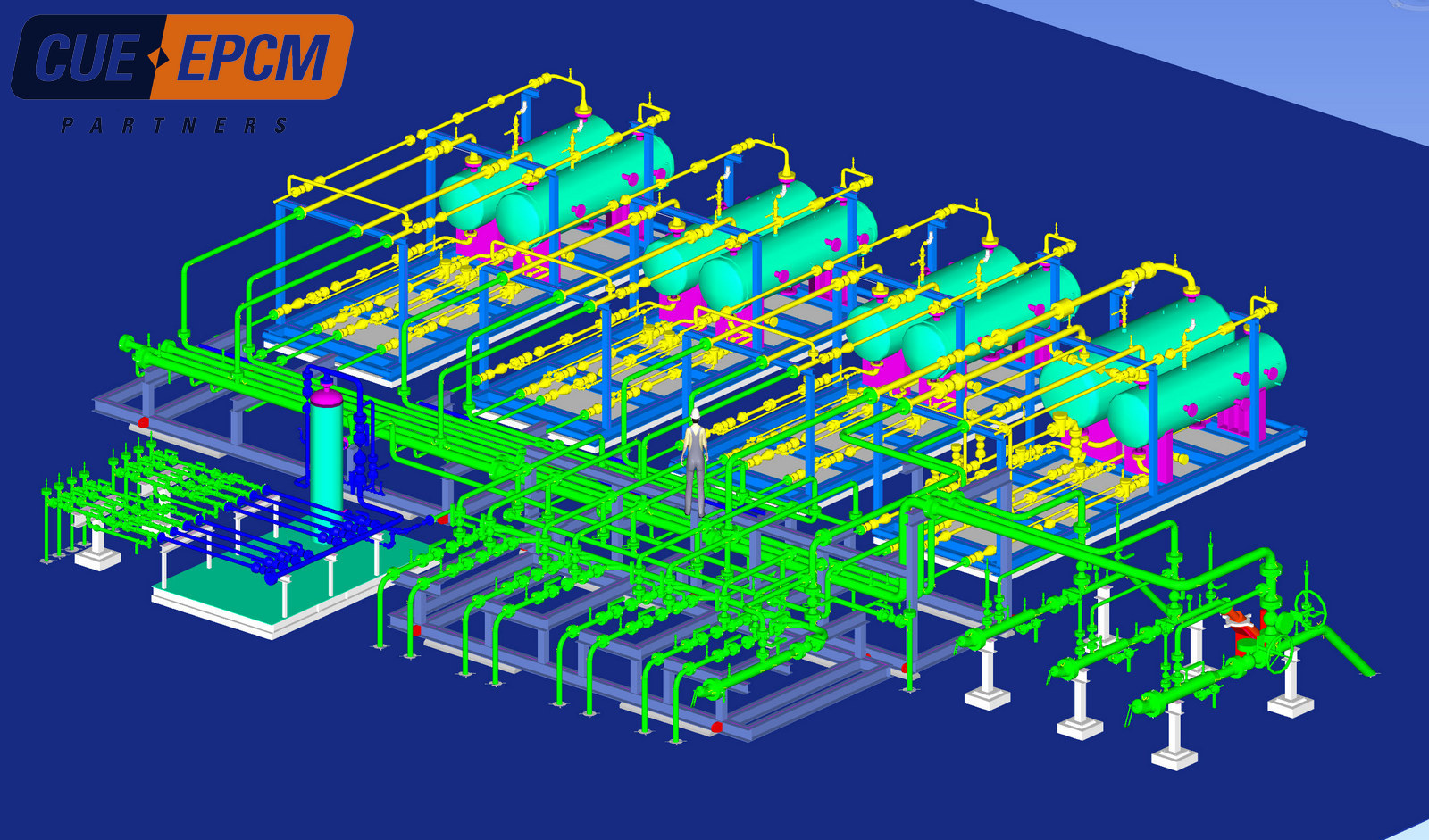

Read More Streamlining Operations: $2.5MM CTB Consolidation Project in the Delaware Basin

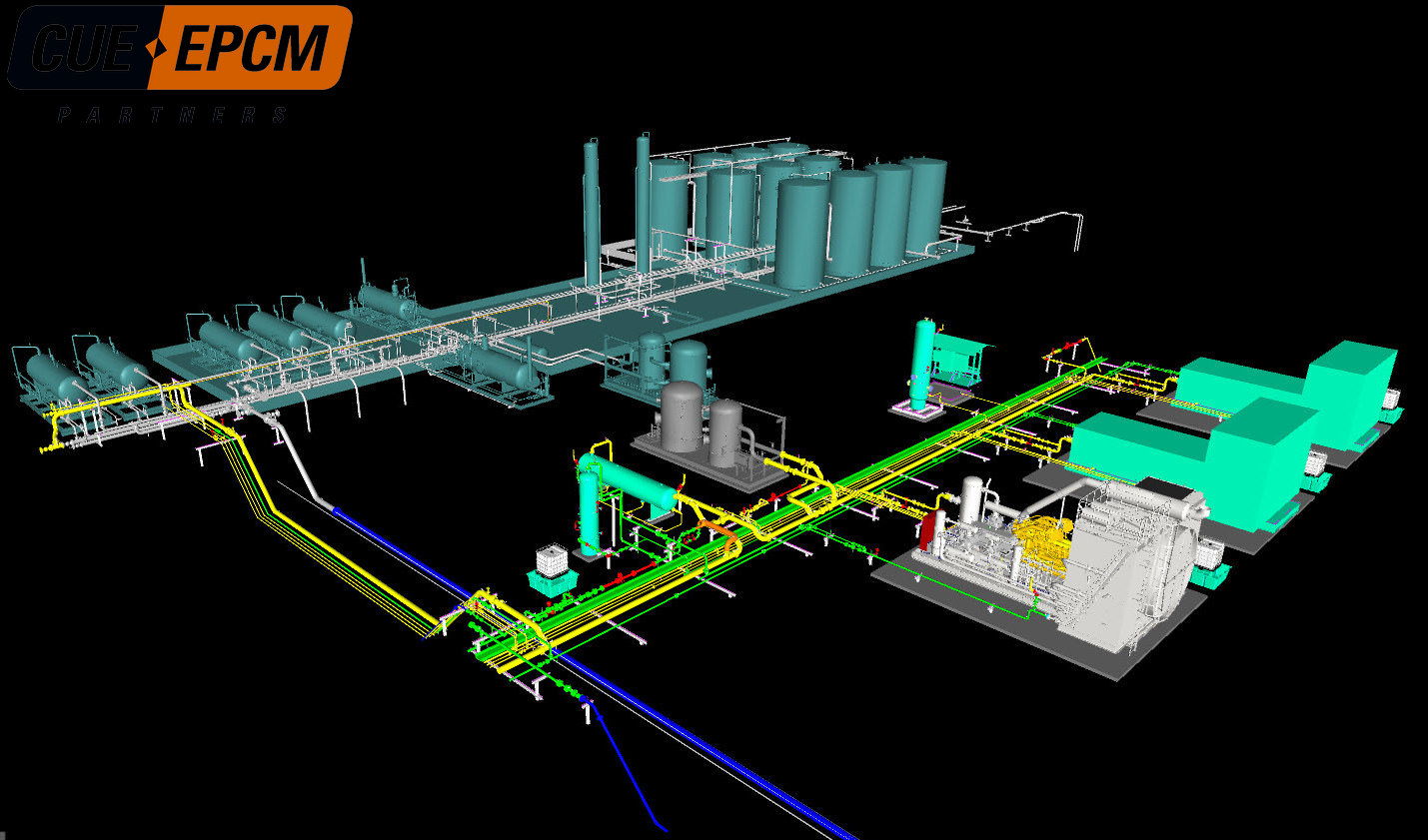

Completed a $2.5MM project to consolidate two CTBs in Delaware, improving efficiency and reducing maintenance. Full scope docs, drawings, and 3D model, managed procurement, oversaw construction, and supported commissioning.

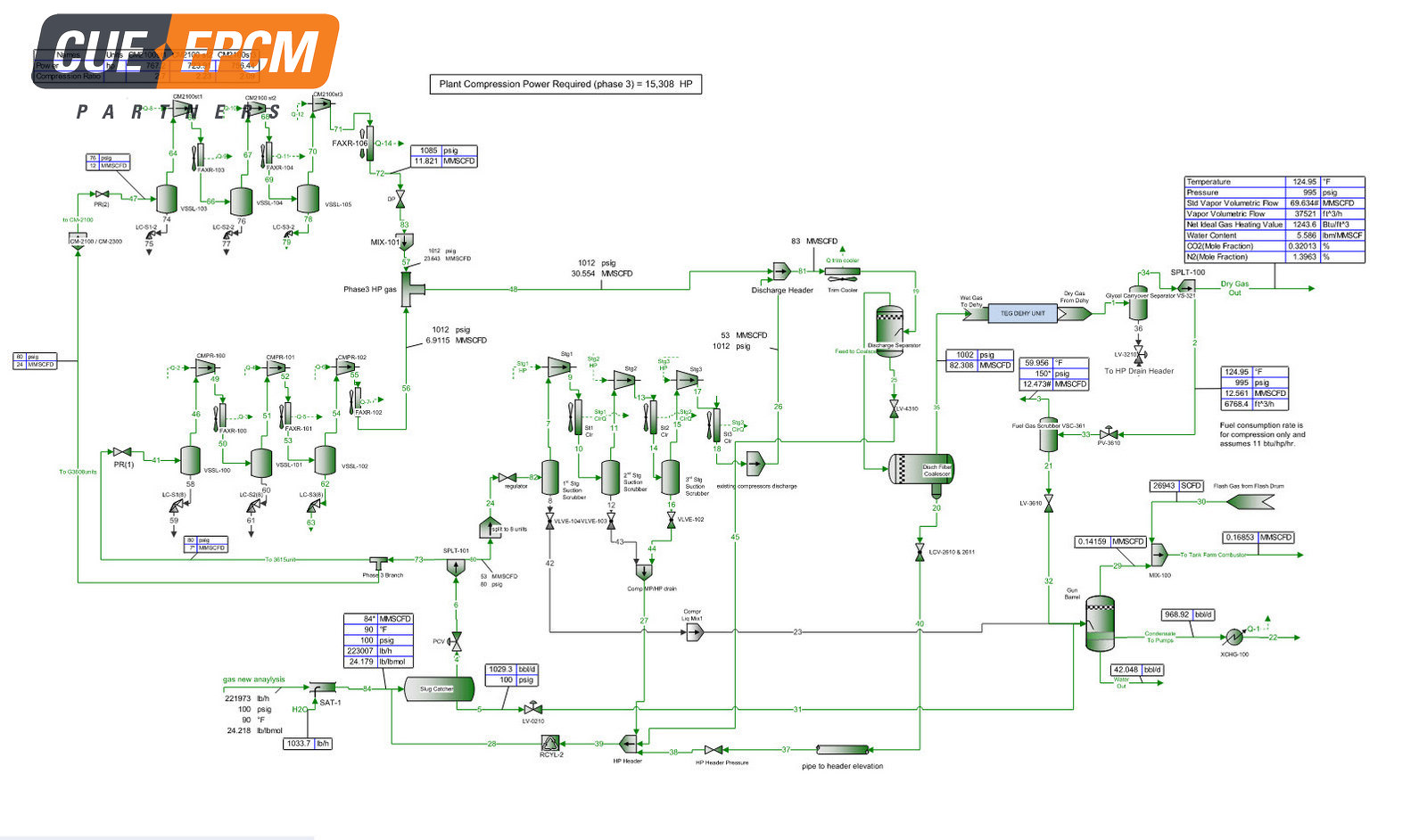

Read More 15,300 HP Bell Lake North Gas Compression Plant Expansion

Supported design and modeling for Bell Lake North Gas Compression Plant (84 MMSCFD). Integrated 10 compressors, discharge separator, and Phase 3 expansion. Optimized pressure control, gas routing, and safety systems to enhance reliability and readiness.

Read More Unlocking Hidden Capacity in Existing Infrastructure

We evaluated an existing CTB to assess capacity for new production tie-ins. Our review covered inlet headers, separation, treating, tanks, pumps, LACT, and flare systems—identifying bottlenecks and providing upgrade recommendations to support increased throughput.

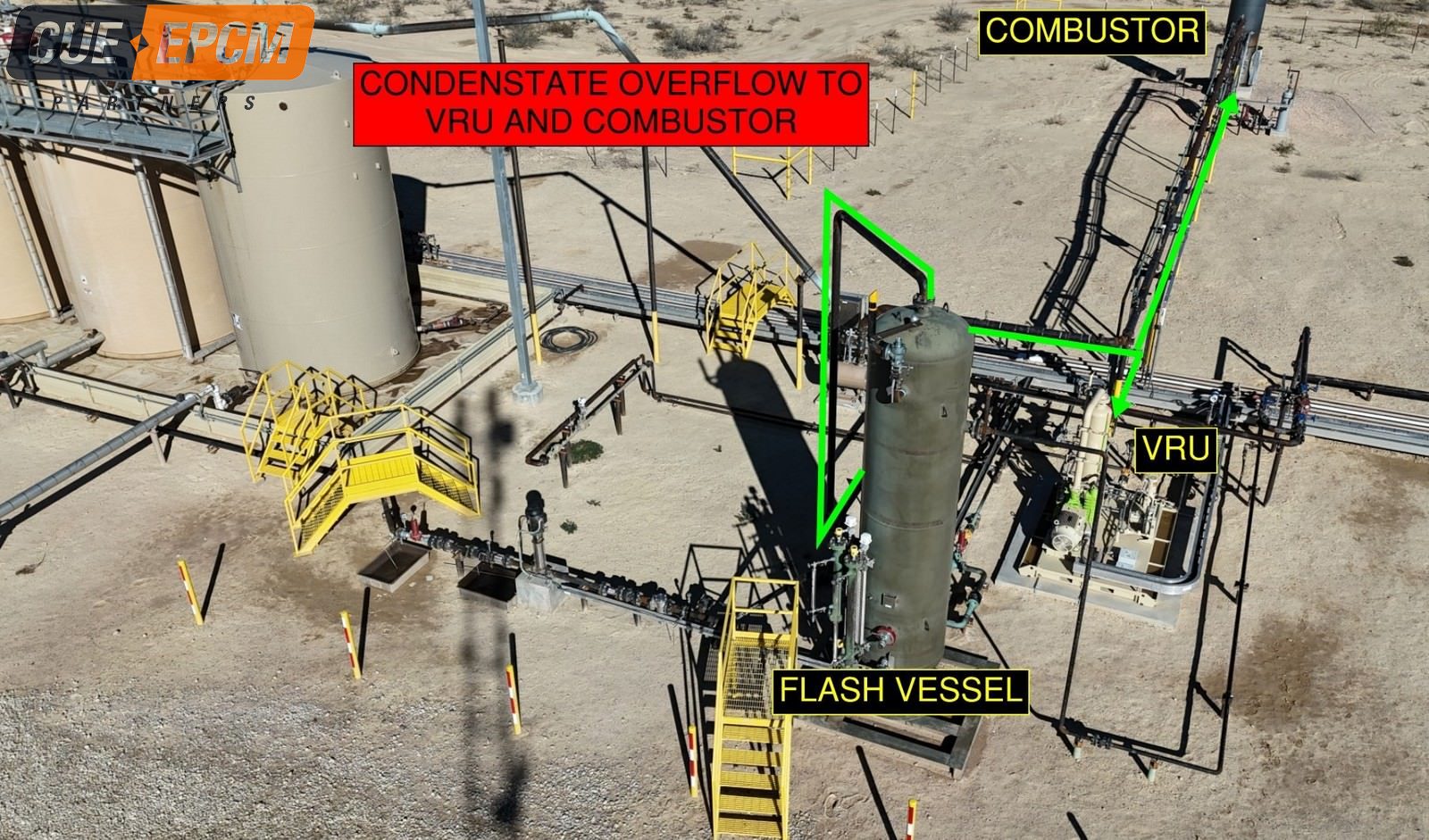

Read More Rapid Response to Compressor Station Fire: Resolving Flash Vessel Overflow

Diagnosed cause of fire at Delaware gas compressor station: flash vessel overflow due to valve misalignment and low NPSHa. Delivered fix in 3 days—pump mods, control changes, and NGL reroute. Client accepted all recommendations.

Read More Optimizing Performance & Reducing Costs: Delaware Oil Battery Emissions Upgrades

Ongoing support at a Delaware gas facility led to over 50 upgrades, VRU optimization, flare system improvements, and cost-saving solutions. We provided ROI analysis and a full bid-ready SOW package to guide future investments and enhance operational reliability.

Read More Meeting EPA Scrutiny: Vent Gas & Safeguarding Upgrades for South Midland Basin 9,000 BBL/d Oil Battery

CUE EPCM conducted a Vent Gas System and Safeguarding Study for our clients’ South Midland Basin CTB facility, recommending upgrades to improve system efficiency, overpressure protection, and fire safety. Key actions included regulator replacements and fire detection system installation.

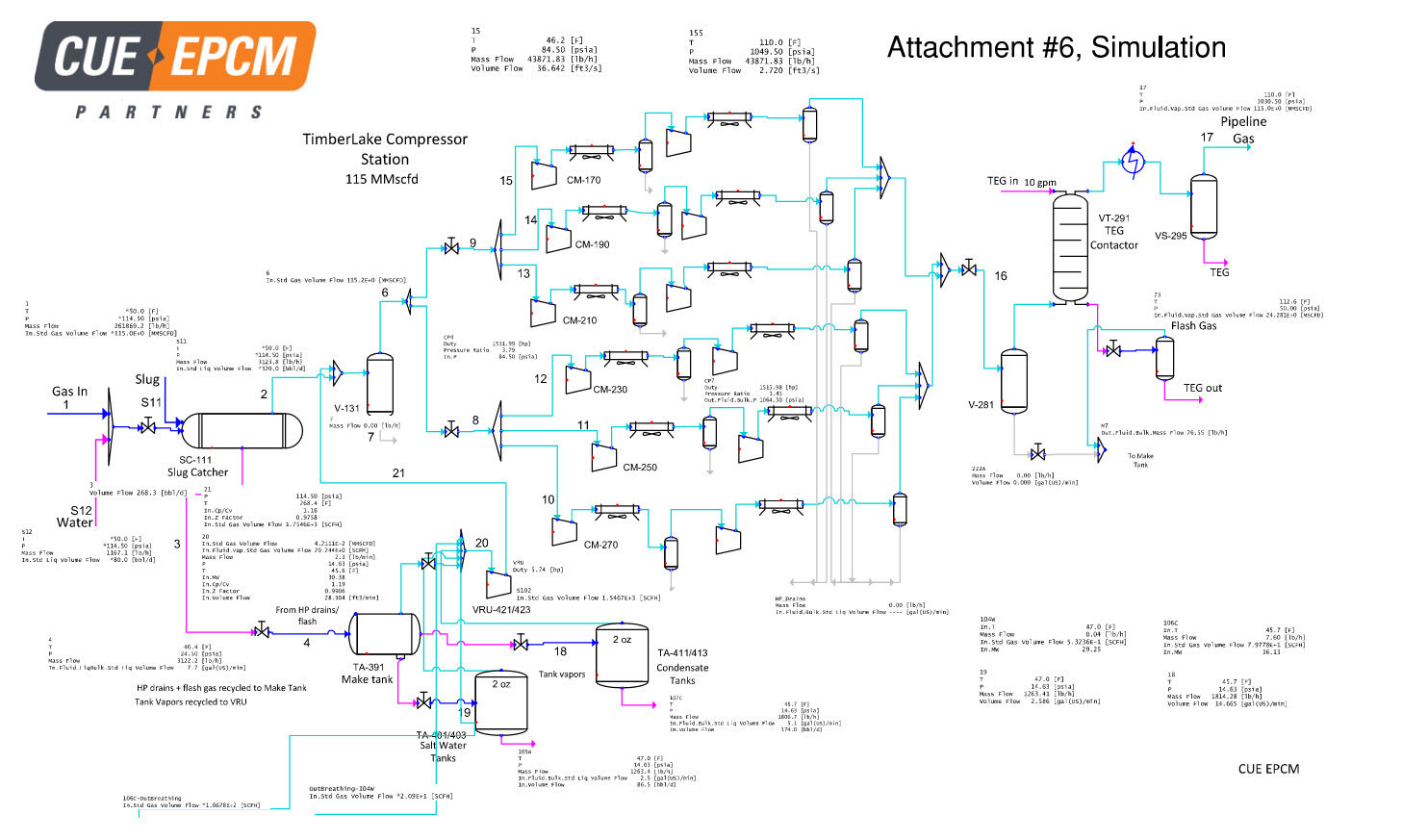

Read More Timber Lake Compressor Station: TEG Dehydration Unit Design and Simulation

CUE EPCM simulated the TEG dehydration unit for Marathon’s Timber Lake Compressor Station, ensuring pipeline gas meets spec at 155 MMscfd. The design removes water to 6.5 lb/MM, includes BTEX controls, and supports future expansion with efficient, reliable performance.

Read More Modular Facility Design Saves Millions in Eagle Ford

We developed modular wellpad systems with relocatable separators and piping skids, saving our Eagle Ford client ~$1.5MM per site. The design boosts efficiency, reduces costs, and accelerates production—positioning them as a leader in scalable facility execution.

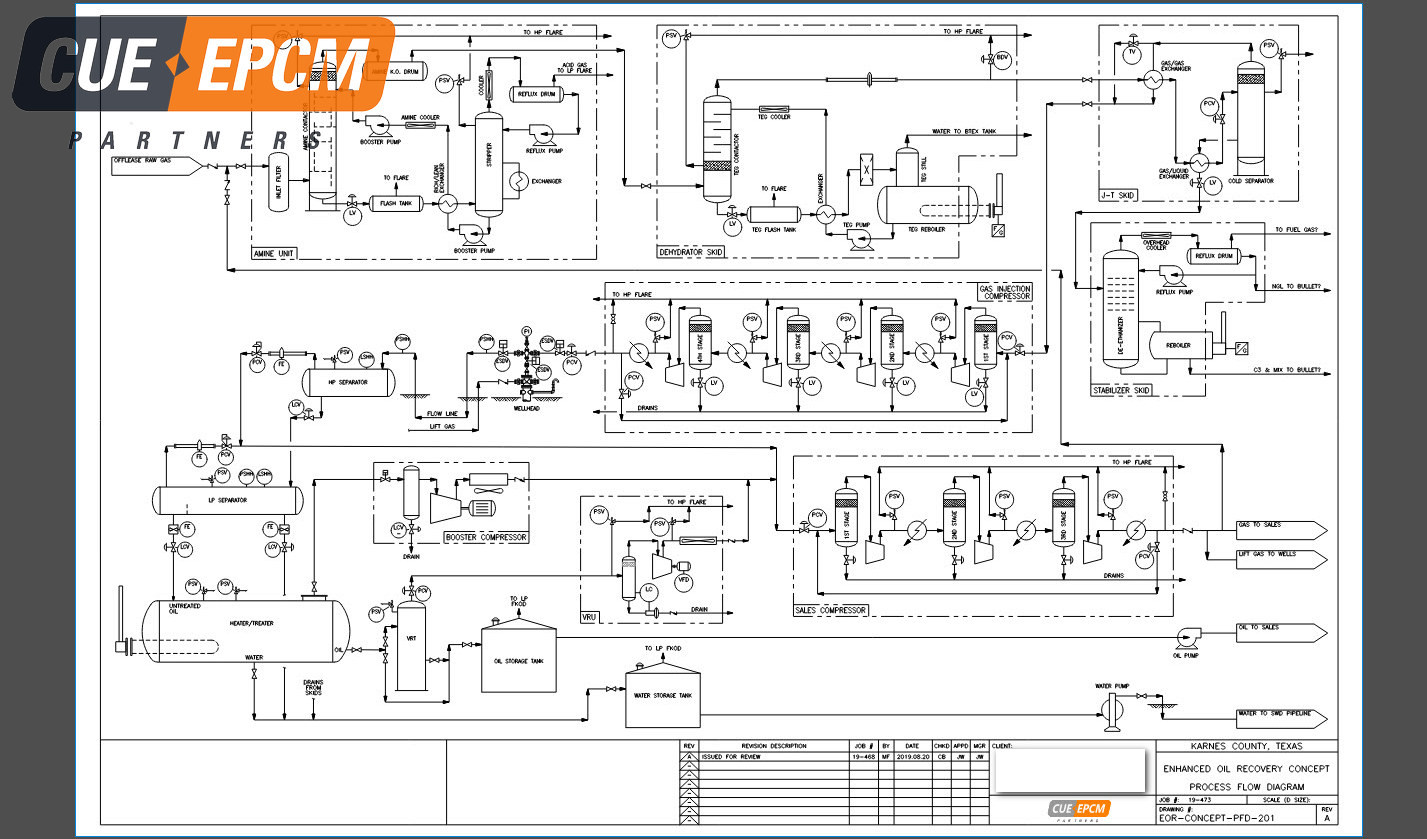

Read More Boosting Barrel Counts: EOR Pilot Design for Eagle Ford Client

CUE delivered detailed design and cost estimate for Eagle Ford client EOR pilot. The project tested huff and puff gas injection at 10,000 psi on two wells over 6 months, aiming to boost recovery from mature assets and extend field life.

Read More